System Maintenance: 7 Essential Steps for Peak Performance

Welcome to the ultimate guide on system maintenance! Whether you’re managing a computer, server, or industrial machinery, regular upkeep is the secret to longevity, efficiency, and reliability. In this comprehensive article, we’ll break down everything you need to know about keeping your systems running like new.

What Is System Maintenance and Why It Matters

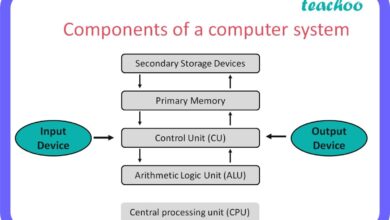

System maintenance refers to the routine activities performed to ensure that a system—be it software, hardware, or a combination of both—operates efficiently and remains free from failures. This proactive approach helps prevent downtime, reduces repair costs, and extends the lifespan of critical assets.

Defining System Maintenance

At its core, system maintenance involves inspecting, testing, repairing, and replacing components before they fail. It applies across various domains, including IT infrastructure, manufacturing equipment, HVAC systems, and even vehicles. The goal is to maintain optimal performance and avoid unexpected breakdowns.

- Preventive actions to avoid system failure

- Regular checks and updates to ensure functionality

- Corrective measures when issues are detected

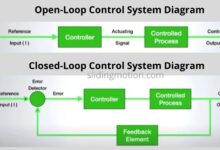

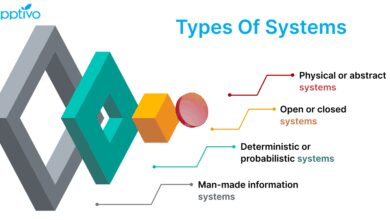

Types of System Maintenance

There are several types of system maintenance, each serving a specific purpose:

- Preventive Maintenance: Scheduled tasks like software updates or hardware cleaning.

- Corrective Maintenance: Actions taken after a failure occurs.

- Predictive Maintenance: Using data and analytics to predict when maintenance is needed.

- Perfective Maintenance: Improving system performance beyond original specifications.

“An ounce of prevention is worth a pound of cure.” – Benjamin Franklin. This timeless quote perfectly captures the essence of effective system maintenance.

The Critical Role of System Maintenance in IT Infrastructure

In the digital age, IT systems are the backbone of nearly every organization. From cloud servers to local networks, consistent system maintenance ensures data integrity, security, and uninterrupted service.

Ensuring Data Security and Integrity

One of the most vital aspects of IT system maintenance is protecting sensitive data. Regular updates to antivirus software, firewalls, and intrusion detection systems help defend against cyber threats. Additionally, maintaining backup protocols ensures data can be recovered in case of corruption or ransomware attacks.

- Apply security patches promptly

- Conduct regular vulnerability scans

- Maintain encrypted, offsite backups

Optimizing Network Performance

Networks require constant monitoring and tuning. System maintenance tasks such as clearing cache, updating router firmware, and managing bandwidth usage can significantly improve speed and reliability. Tools like Wireshark allow administrators to analyze traffic and identify bottlenecks.

- Monitor network latency and packet loss

- Update firmware on networking devices

- Implement Quality of Service (QoS) policies

System Maintenance in Industrial and Mechanical Systems

Beyond the digital world, physical systems also rely heavily on maintenance. In manufacturing, energy, and transportation sectors, equipment failure can lead to costly downtime and safety hazards.

Preventing Equipment Downtime

Unplanned downtime in industrial settings can cost thousands per hour. Regular system maintenance, such as lubricating moving parts, inspecting belts and motors, and calibrating sensors, helps avoid sudden failures. Predictive tools like vibration analysis and thermal imaging are increasingly used to detect early signs of wear.

- Schedule routine inspections

- Use IoT sensors for real-time monitoring

- Train staff on early warning signs

Safety and Compliance Standards

Maintenance isn’t just about performance—it’s also a legal and safety requirement. Regulatory bodies like OSHA (Occupational Safety and Health Administration) mandate regular maintenance of machinery to protect workers. Failure to comply can result in fines or shutdowns.

- Follow manufacturer-recommended service intervals

- Document all maintenance activities

- Ensure compliance with ISO and ANSI standards

According to the U.S. Department of Energy, proper maintenance can reduce energy consumption in industrial systems by up to 20%.

Software System Maintenance: Keeping Applications Running Smoothly

Software doesn’t wear out like hardware, but it still requires ongoing system maintenance to remain functional, secure, and user-friendly. This is especially true for enterprise applications, operating systems, and web platforms.

Code Refactoring and Bug Fixes

Over time, software accumulates technical debt—inefficient code, deprecated libraries, and unresolved bugs. Regular system maintenance includes refactoring code to improve readability and performance. Developers also fix bugs reported by users or detected through automated testing.

- Use version control systems like Git

- Run automated unit and integration tests

- Address user feedback promptly

Updating Dependencies and Libraries

Modern software relies on third-party libraries and frameworks. These dependencies must be updated regularly to patch security vulnerabilities and ensure compatibility. Tools like Dependabot can automate this process, alerting developers when updates are available.

- Monitor for deprecated packages

- Test updates in staging environments

- Maintain a software bill of materials (SBOM)

The Role of Automation in System Maintenance

As systems grow in complexity, manual maintenance becomes impractical. Automation tools have revolutionized how organizations handle system maintenance, making it faster, more accurate, and scalable.

Automated Monitoring and Alerts

Tools like Nagios, Zabbix, and Datadog provide real-time monitoring of system health. They track CPU usage, memory consumption, disk space, and network activity. When thresholds are exceeded, automated alerts notify administrators before issues escalate.

- Set up dashboards for key performance indicators (KPIs)

- Configure alerting via email, SMS, or Slack

- Integrate with incident management systems

Scheduled Maintenance Scripts

Many routine tasks—such as log rotation, database cleanup, and backup jobs—can be automated using scripts. For example, cron jobs on Linux systems allow administrators to schedule tasks at specific intervals. This reduces human error and ensures consistency.

- Write shell or PowerShell scripts for repetitive tasks

- Use task schedulers like cron or Windows Task Scheduler

- Log script outputs for audit trails

Automation doesn’t eliminate the need for human oversight—it enhances it by freeing up time for strategic decision-making.

Best Practices for Effective System Maintenance

To get the most out of your system maintenance efforts, it’s essential to follow proven best practices. These guidelines apply across industries and help ensure consistency, accountability, and long-term success.

Create a Comprehensive Maintenance Plan

A well-documented maintenance plan outlines what tasks need to be performed, how often, and by whom. It should include checklists, schedules, and escalation procedures. This plan serves as a roadmap for both routine and emergency maintenance.

- Define maintenance windows to minimize disruption

- Assign responsibilities to team members

- Include contingency plans for critical systems

Document Every Maintenance Activity

Documentation is crucial for tracking performance trends, auditing compliance, and training new staff. Every maintenance task—whether preventive or corrective—should be logged with details such as date, technician, parts replaced, and observations.

- Use a centralized CMDB (Configuration Management Database)

- Attach photos or logs when applicable

- Make records accessible to authorized personnel

Emerging Trends in System Maintenance

The field of system maintenance is evolving rapidly, driven by advances in artificial intelligence, machine learning, and the Internet of Things (IoT). Staying ahead of these trends can give organizations a competitive edge.

Predictive Maintenance Using AI

Predictive maintenance leverages AI algorithms to analyze historical and real-time data from sensors. By identifying patterns, these systems can forecast when a component is likely to fail, allowing maintenance to be performed just in time—reducing unnecessary servicing and maximizing uptime.

- Use machine learning models to detect anomalies

- Integrate with cloud-based analytics platforms

- Start with pilot projects before full-scale deployment

IoT-Enabled Smart Maintenance

IoT devices are transforming maintenance by providing continuous monitoring of equipment conditions. Smart sensors can measure temperature, pressure, vibration, and humidity, sending data to centralized systems for analysis. This enables remote diagnostics and faster response times.

- Deploy wireless sensors on critical machinery

- Use edge computing to process data locally

- Ensure robust cybersecurity for connected devices

According to a report by MarketsandMarkets, the global predictive maintenance market is expected to grow from $3.7 billion in 2020 to $12.6 billion by 2025.

Common Challenges in System Maintenance and How to Overcome Them

Despite its importance, system maintenance often faces obstacles such as budget constraints, lack of skilled personnel, and resistance to change. Recognizing these challenges is the first step toward overcoming them.

Budget and Resource Limitations

Many organizations underfund maintenance, prioritizing short-term savings over long-term reliability. However, neglecting system maintenance can lead to much higher costs down the line. To justify investment, present data showing how maintenance reduces downtime and extends asset life.

- Calculate return on investment (ROI) for maintenance programs

- Seek grants or incentives for energy-efficient upgrades

- Outsource non-core maintenance tasks if needed

Skill Gaps and Training Needs

As technology advances, maintenance teams must keep up with new tools and methodologies. Providing regular training ensures staff are equipped to handle modern systems. Online platforms like Coursera and LinkedIn Learning offer courses on topics ranging from ITIL to industrial automation.

- Develop a continuous learning culture

- Certify technicians in relevant technologies

- Partner with vendors for specialized training

What is the primary goal of system maintenance?

The primary goal of system maintenance is to ensure that systems operate efficiently, reliably, and securely by preventing failures, extending lifespan, and minimizing downtime through regular inspection, updates, and repairs.

How often should system maintenance be performed?

The frequency depends on the system type and usage. IT systems may require weekly updates and monthly checks, while industrial equipment might follow manufacturer-recommended schedules—often quarterly or semi-annually. Critical systems may need daily monitoring.

What are the cost benefits of regular system maintenance?

Regular system maintenance reduces unexpected repair costs, extends equipment life, improves energy efficiency, and prevents costly downtime. Studies show that proactive maintenance can save organizations up to 30% in operational costs over time.

Can system maintenance be fully automated?

While many tasks can be automated—such as software updates, backups, and monitoring—human oversight remains essential for decision-making, complex repairs, and strategic planning. The ideal approach combines automation with skilled personnel.

What tools are commonly used in system maintenance?

Common tools include monitoring software (e.g., Nagios, Datadog), automation platforms (e.g., Ansible, Puppet), diagnostic utilities (e.g., Wireshark, Task Manager), and CMMS (Computerized Maintenance Management Systems) for tracking work orders and inventory.

In conclusion, system maintenance is not just a technical necessity—it’s a strategic imperative. Whether you’re managing digital infrastructure or physical machinery, a well-structured maintenance program ensures reliability, safety, and cost-efficiency. By embracing best practices, leveraging automation, and staying ahead of emerging trends like AI and IoT, organizations can maximize uptime and performance. Remember, the key to success lies in consistency, documentation, and continuous improvement. Don’t wait for a breakdown to act—start building your maintenance strategy today.

Further Reading: